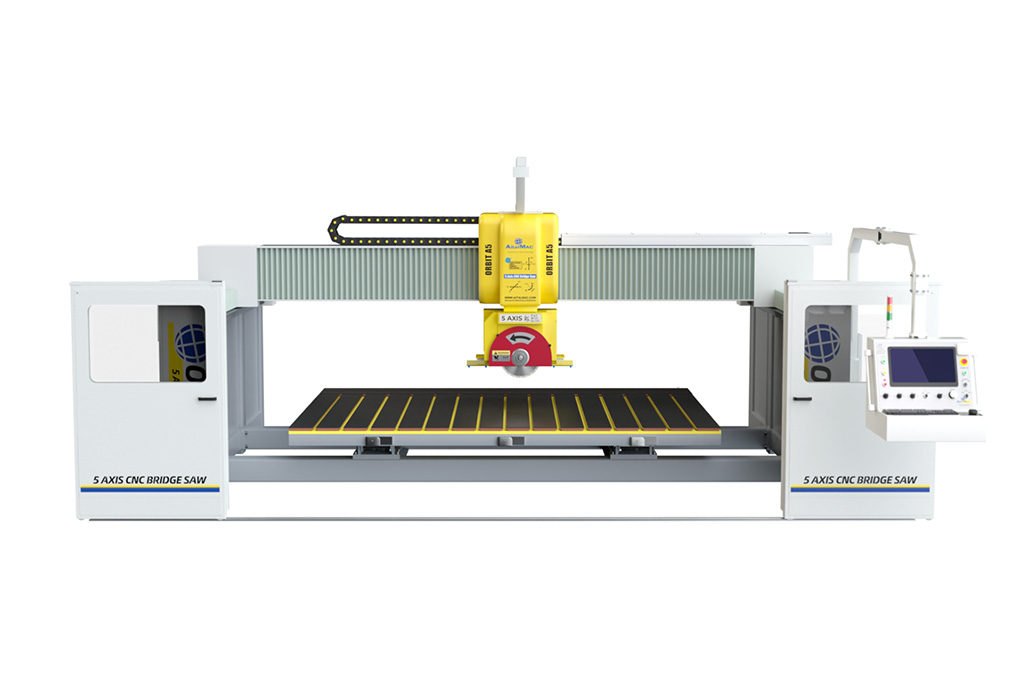

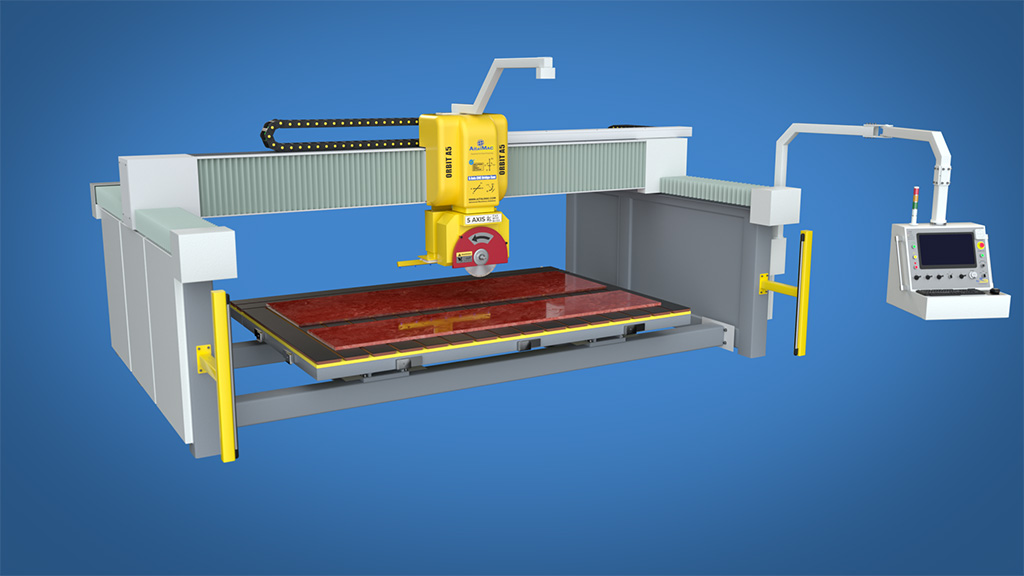

5 axis CNC Bridge Saw Orbit A5

This bridge saw has everything a technologically advanced bridge saw needs to have today: 5 interpolated axis, spindle with half inch fitting with trough-spindle lubrication, tilting table up to 85°, vacuum manipulator system for parts movement during automatic cut process, on-board camera, blade presetting and stone thickness probe.The machine in details

- This machine is a fully interpolated 5 axis bridge saw. The Y axis is moved by a gantry system. This guarantees a perfect square of the bridge. Automatic head rotation from 0° to 400° combined with automatic blade tilting from 0° to 90° makes it suitable for large production runs, at the same time containing costs.

- The absolute precision of the movements is guarantee by a state of art transmission on linear ball guide, moved by brushless motors through high precision helical gears and racks.

- This machine comes with the “absolutely zero” technology, which allow the machine to work without doing the homing process.

- It has an extremely easy to use interface, realized to facilitate the interaction between the operator and the machine.

- It can quickly do easy cuts in manual, the machine also can import and work with DXF (AutoCAD) files and “G-code” ( RS-274 machine tool programming language).

- The cable-drag chain and the electric cables used on the machine are purposely made for use at high speed (robot materials).

CNC Controller & Software

Easy to use interface. Imports and works with DXF files and G-Code, but can also do simple cuts in manual mode.

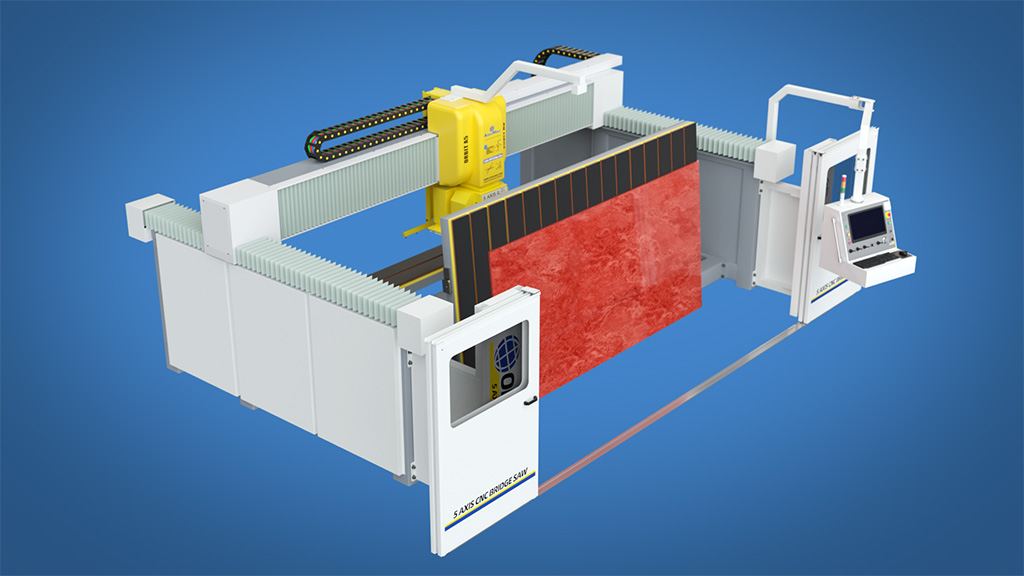

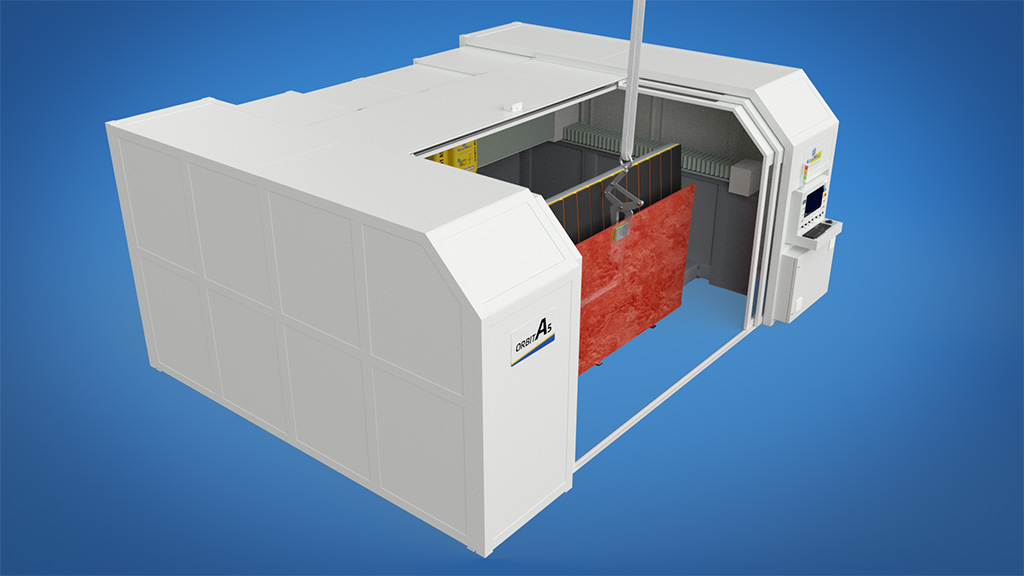

Tilting table up to 85°

Table tilts up to 85°, enabling the easy loading of your slabs.

DXF Digital templater

This machine is equipped with a system to digitize templates. Using a laser pointer, it’s possible to acquire points and save them in a DXF file.

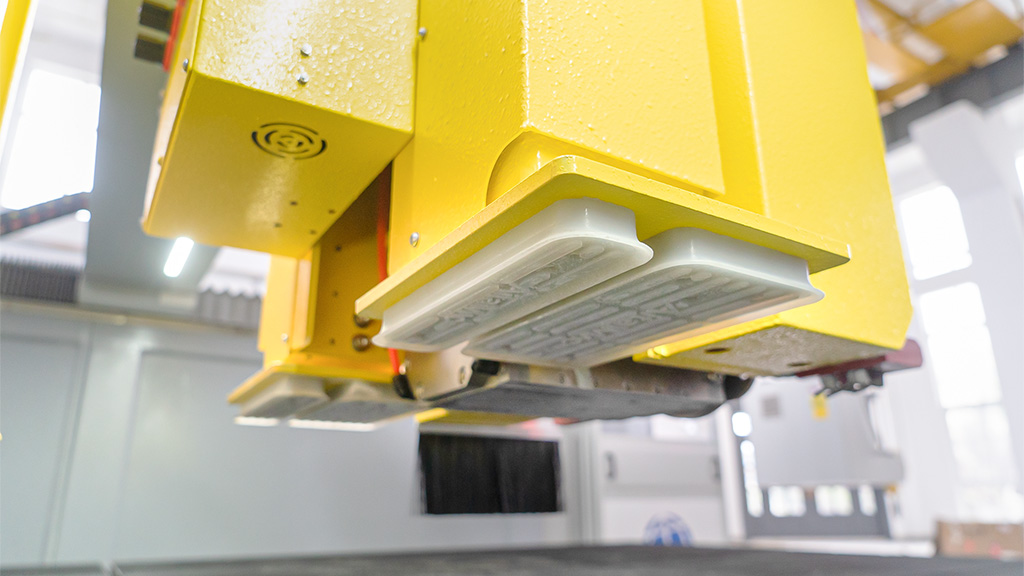

Vacuum manipulator system

The manipulator system has four vacuum cups, enabling a lift capacity of 500kg / 1100lbs.

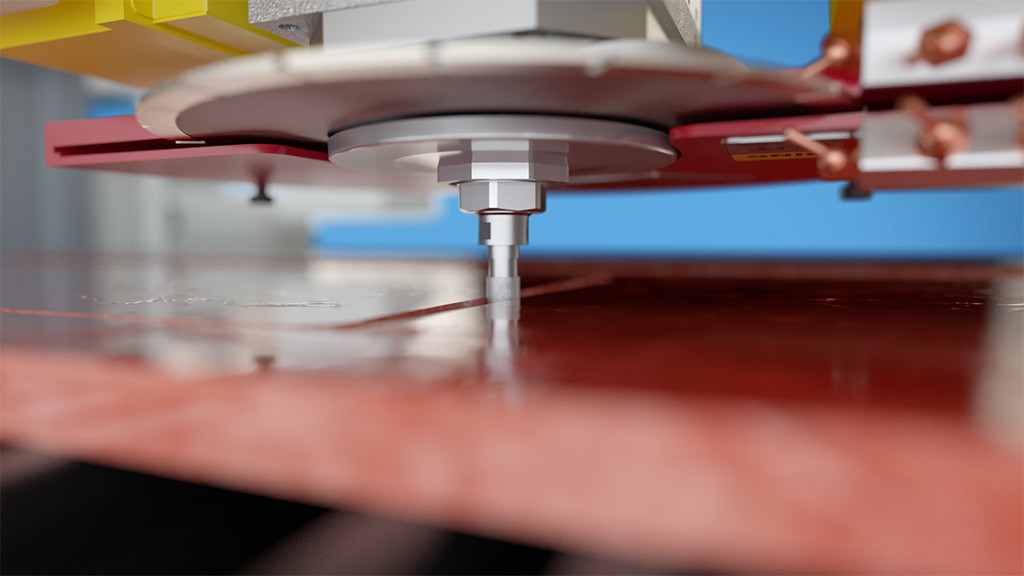

Stone & Blade probe

The stone probe and blade probe enable the machine to process the stone more accurately.

Spindle with half inch fitting

1/2” GAS fitting with internal water for fingerbits, engraving, polishing and drain boards.

washing apparatus

Included in the machine a slab washing apparatus that isusedtowhash the stone before the vacuum manipulations.

On-board camera

The machine is supplied with an on-board camera with a precision of +/- 5mm. With the camera is possible to snap a picture of the slab, and then import the picture in the program to place your parts avoiding defects.

Option

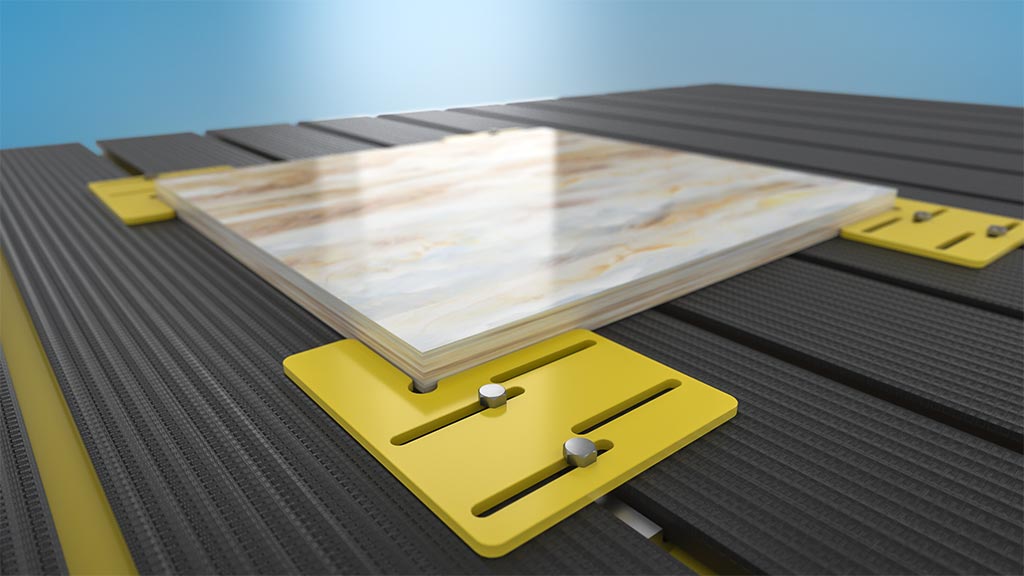

Fixture system

The table is made out of 3 layers of different materials. It’s possible to block parts using convenient fixtures (supplied with machine) that will hook on the table slots milled on the central table layer. This provides a good fixture system that allows to lock the parts on the table when doing heavy jobs.

AITEK 9 AXIS CNC CONTROLLER:

- Automatic updates trough internet

- Direct error report to AitalMAC

- Direct connection for remote assistance

- Tool manager

- Tool compensation management

- Backlash compensation

- Self-diagnosis system

- Access to driver for Aitalmac assistance

- Online monitoring system

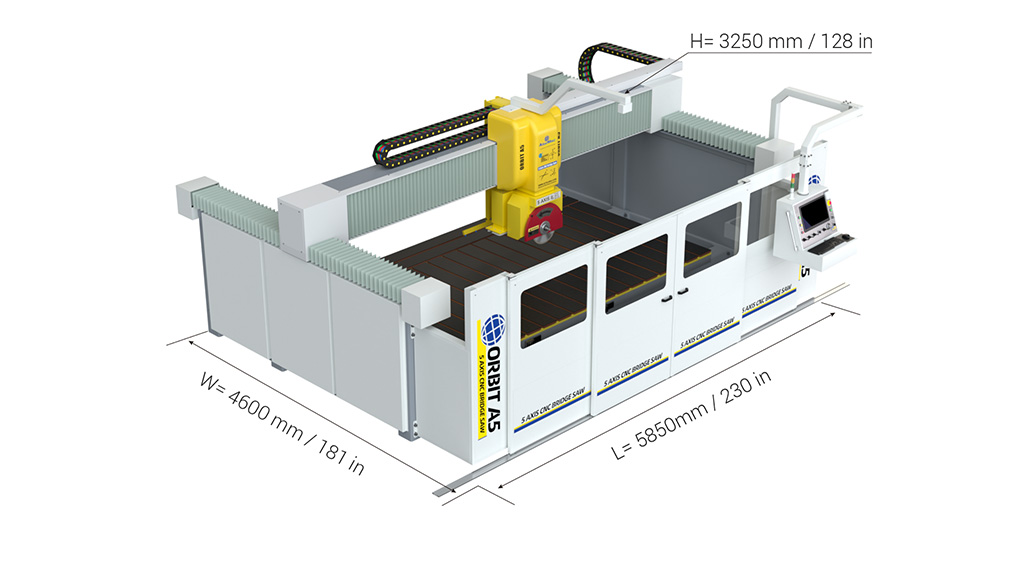

| Overall dimensions | 5850 × 4600 × 3250 mm / 230 × 181 × 128 in. |

|---|---|

| Total weight | 7500 kg / 16535 lbs |

| Max. Install power | 22 kW |

| Table size | 3600 x 2450 mm / 141-3/4 x 96-1/2 in. |

| Linear axis travel (X-Y-Z) | 3700 - 2800 - 380 mm / 146 - 110 - 15 in. |

| Rotary axis travel (B-C) | 90° - 540° |

| Max linear speed (X-Y-Z) | 30 - 30 - 7.5 m/min / 98 - 98 - 24 ft/min |

| Max rotation speed (B&C) | 3600 °/min |

| Maximum blade diameter | 500 mm / 20 in. (600 mm / 24 in. Optional) |

| Cutting disc hole diameter | 50 mm /1.96 in |

| Cutting disc flange diameter | 200 mm / 7.87 in. |

| Max cut thickness vertical | 150 mm / 6 in. |

| Electric spindle power | 15 kW (s1) |

| Maximum spindle rotation | 9000 RPM |

| Vacuum cups | 4 number |

| Vaccum lift capacity | 500 kg / 1100 lbs |

| Air pressure required | 7 bar |

| Water consumption | 15~25 l/min / 4~6.5 gal/min |