5 axis CNC Bridge Saw BK2020 5+V

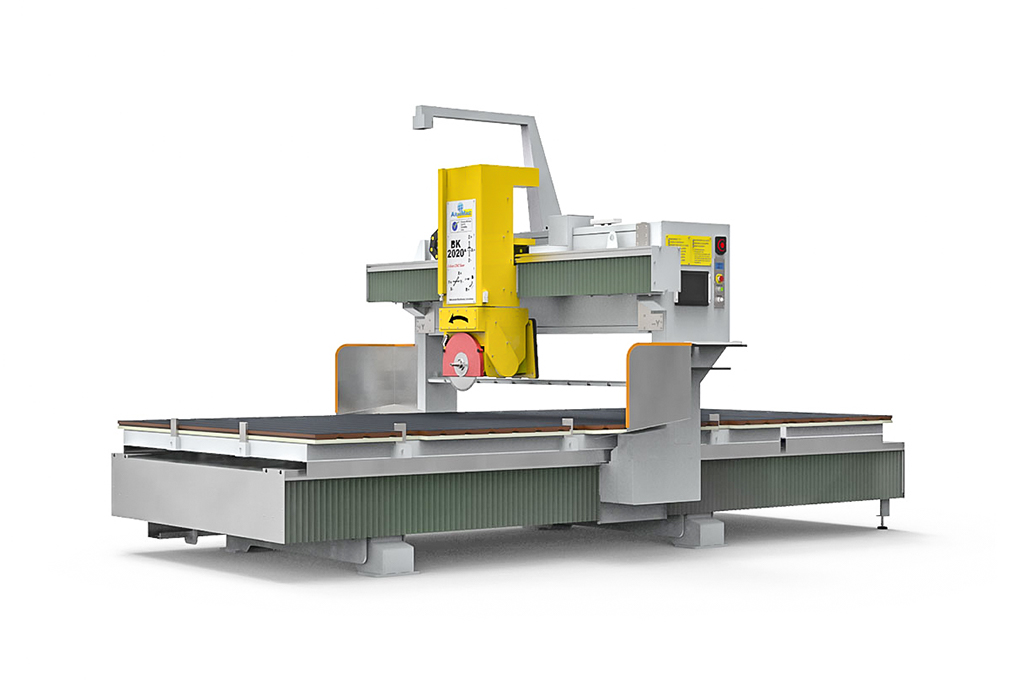

This bridge saw has everything a technologically advanced bridge saw needs to have today: 5 interpolated axis, spindle with half inch fitting with trough-spindle lubrication, tilting table up to 85°, vacuum system for parts movement during automatic cut process, on-board camera, blade and stone thickness probe (optional).Relationship between the slab size and overall size of the machine

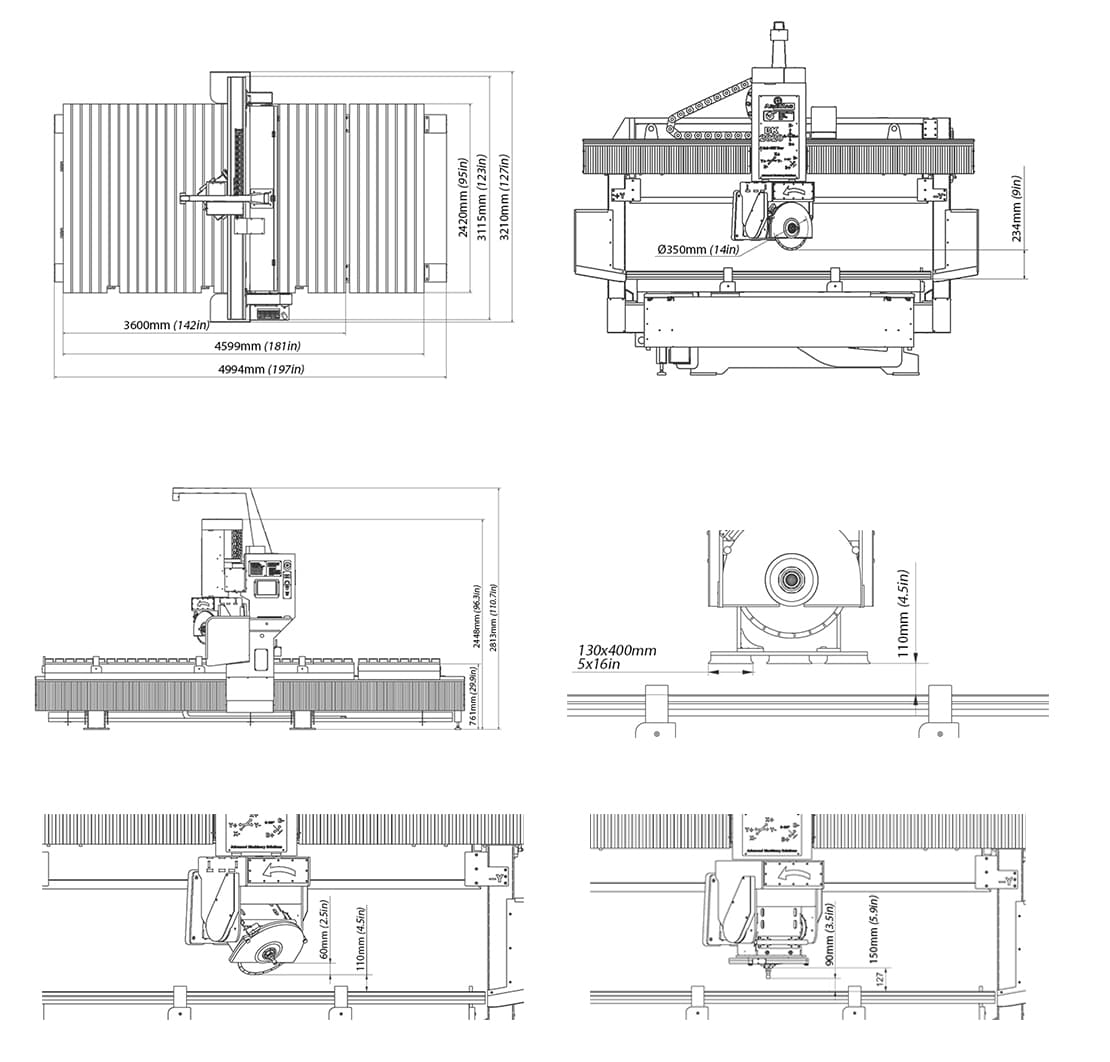

The first evident advantage is the ratio between working area and overall machine dimensions.

This machine with a working area of 4000mm x 2420mm occupies only 15.5 square meters, making it possible to fit two machines in the space of a traditional bridge saw.

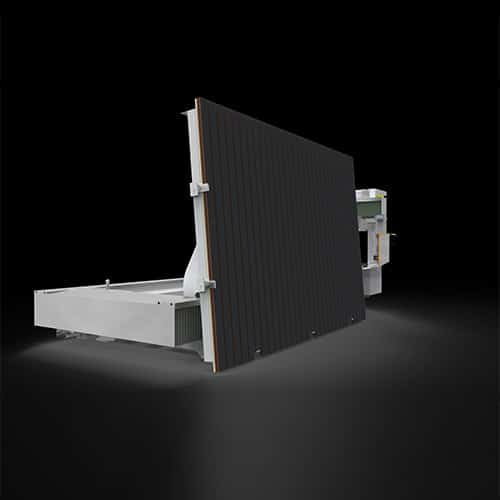

Easy unload of parts from the table

The table has three sides that are always accessible to the operator, who can then unload parts more easily and more safely.

Increased rigidity of the machine

The guides of the bridge are anchored to the ground and thus provide a better rigidity to the whole machine.

Bridge resistance to twisting

5-axis bridge saws are exposed to always-changing twist forces, because the blade cutting direction is not always parallel to the bridge.

The shorter bridge solidly anchored, not on wheels or rollers, has greatly improved twist resistance.

Improved Z axis rigidity

An improved motor tilting system combined with a correctly sized blade allowed us to lower the bridge and to shorten the Z slide.

The shorter Z frontally mounted on the bridge has increased rigidity but kept the same working height capacity.

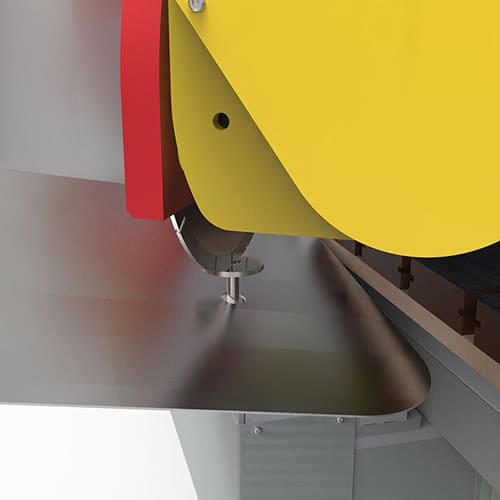

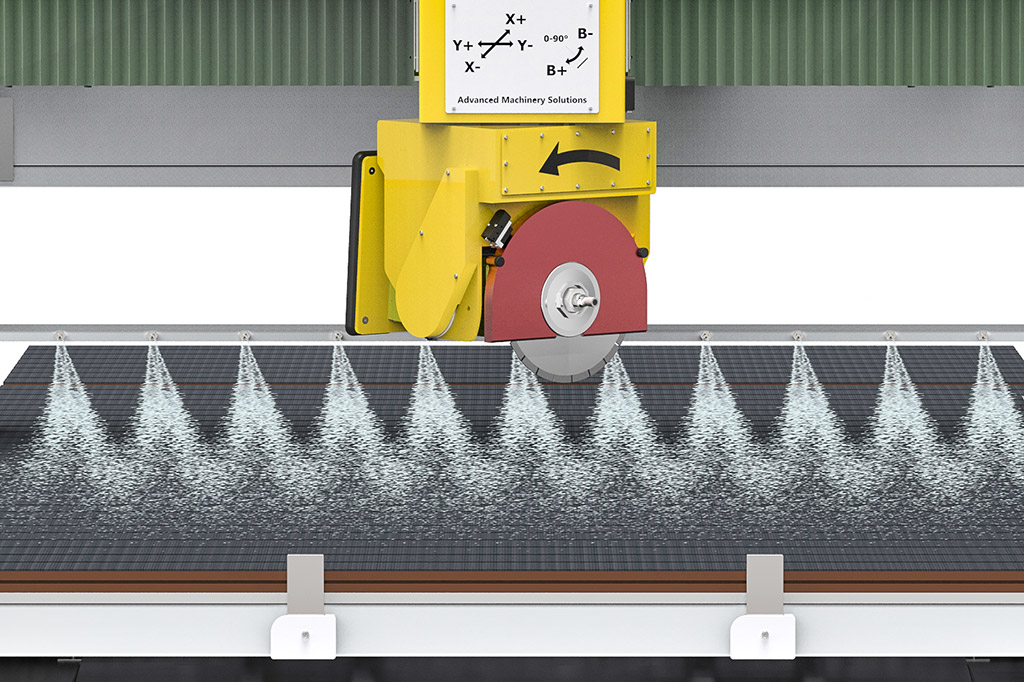

Lower water consumption

The traditional cooling system expects huge quantity of water to cool 30% of the blade perimeter, or only the contact side, this cover (patent n° 3684608) keeps the blade submerged in water for 70% of the perimeter.

Cooling trough submersion needs less water and almost totally eliminate water splashes.

Rapid movements

The smaller size of the machine allows it to reach a point before compared to a larger machine.

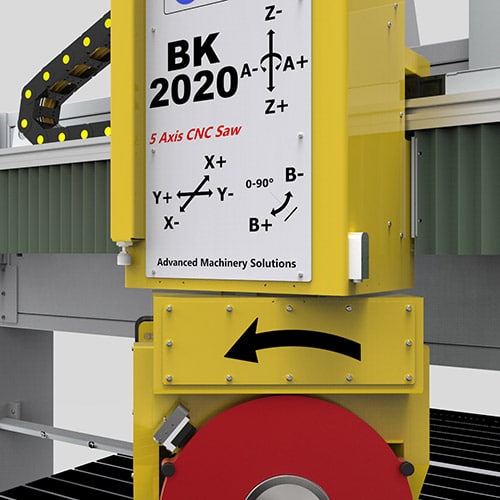

Blade motor with vector technology

A vector motor and an induction motor have different performance.

With the same consumption (kW) the vector motor has twice the torque (Nm).

Vector motor technology allows the motor to keep a constant torque up to 6000 rpm, instead with an induction motor, even if controlled by VFD, as the speed increases it loses torque, but the consumption increases.

Using vector motor technology allowed us to increase performance, and drastically reduce consumption and the dimensions of the blade motor.

Increased cutting depth

The motor and flange diameter of only 160mm allows cutting 100mm thick stone with a blade of only 360mm diameter.

With a traditional motor you would instead need a 450mm blade to cut the same thickness.

Better cutting performance

A small blade because it’s thinner reduces sludge left from the cutting process, also because it’s cutting less it can cut faster, and it leaves shorter overcuts. Another advantage of a small blade is that it requires less water and less power to run.

Machine installation

Machine’s mono-block structure allows installation in less than a full working day on a flat concrete floor, without needing to spend more to build walls or special foundations.

Machine structure

The steel structure, is welded, hot galvanized and powder painted.The X rails and Y bridge are made from a thick aluminum extrusion, treated against oxidation and covered with stainless steel.

Gantry bridge

The bridge is mounted on the basement and it moves through two brushless motors in gantry (X1 and X2 axis), they home separately to make sure your bridge is always square, by removing the fixed mechanical transmission backlash and twist are also gone.

Low cabin (optional)

Low cabin for complete water and sludge collection (optional)It’s possible to enclose the machine in a stainless steel low cabin for water and sludge collection.

Control station (optional).

Available on request a secondary control panel (optional).This panel includes a PC for CAD drawings (lower) and a mirror of the machine control panel still available on the side of the machine.

This control panel it’s designed for those who needs to do CAD drawings on the machine

Vacuum pump

The machine is supplied with a liquid-ring pump.

Tilting table

The table can be tilted up to 85° thanks to two hydraulic cylinders.

Slab probe (optional)

A slab thickness probe(optional) can be purchased with the machine.

Vacuum lifter

The group is composed of 3 vacuums 130 x 400 mm, controlled independently. Max capacity 200 kg each.

Tool presetting

The machine is supplied with a blade diameter probe.

Lubrication system

The centralized grease lubrication system is automatically controlled by the machine software.

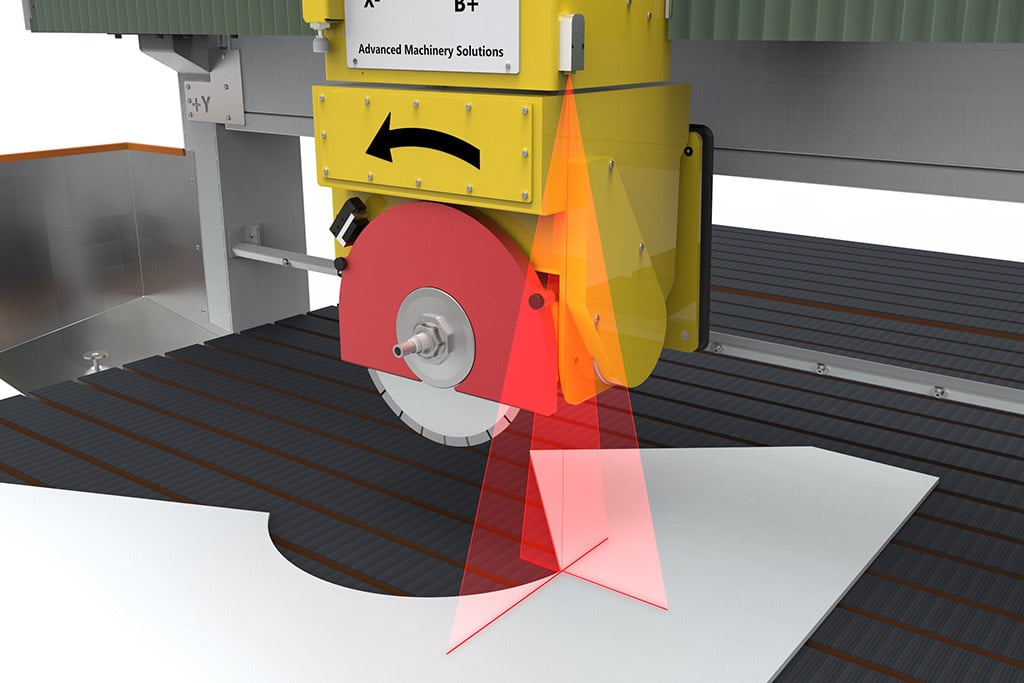

Pendant

It’s included a pendant to make manual cuts.With the help of the linear laser it’s easy to follow templates and markings.

On-board camera

The machine is supplied with an on-board camera with a precision of +/- 2mm.With the camera is possible to snap a picture of the slab, and then import the picture in the program to place your parts avoiding defects.

Slab washing system

Included in the machine a slab washing system.

DXF Laser templater

The machine is equipped with a system to digitize templates, using a laser pointer it’s possible acquire points and save them in a DXF file, that can be used in CAD.

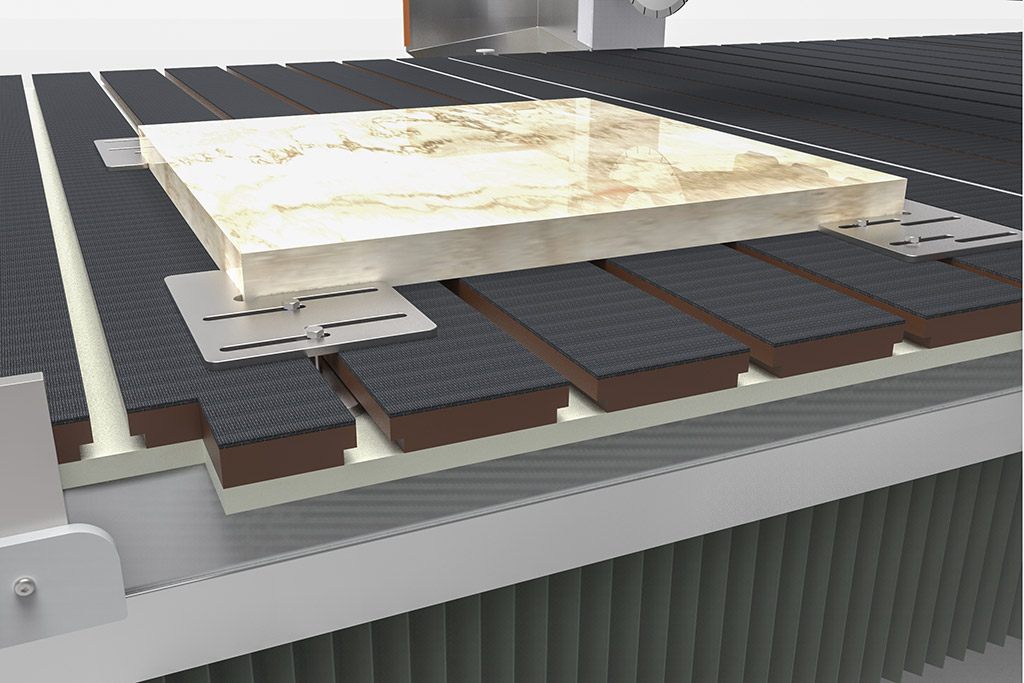

Fixture system

The table is made out of 3 layers of different materials.It’s possible to block parts using convenient fixtures (supplied with machine) that will hook on the table slots milled on the central table layer.

This provides a good fixture system that allows to lock the parts on the table when doing heavy jobs.

High performance wireless router

The machine is equipped with a wireless router that connects it on the Internet and to your corporate network.Furthermore, connectivity is used to keep up to date the CNC and allows the service department to remotely connect to the system.

Aitek 9 axis CNC Controller

• Automatic updates trough internet• Direct error report to AitalMAC

• Direct connection for remote assistance

• Tool manager

• Tool compensation management

• Backlash compensation

• Self-diagnosis system

• Access to driver for Aitalmac assistance

• Online monitoring system

Software

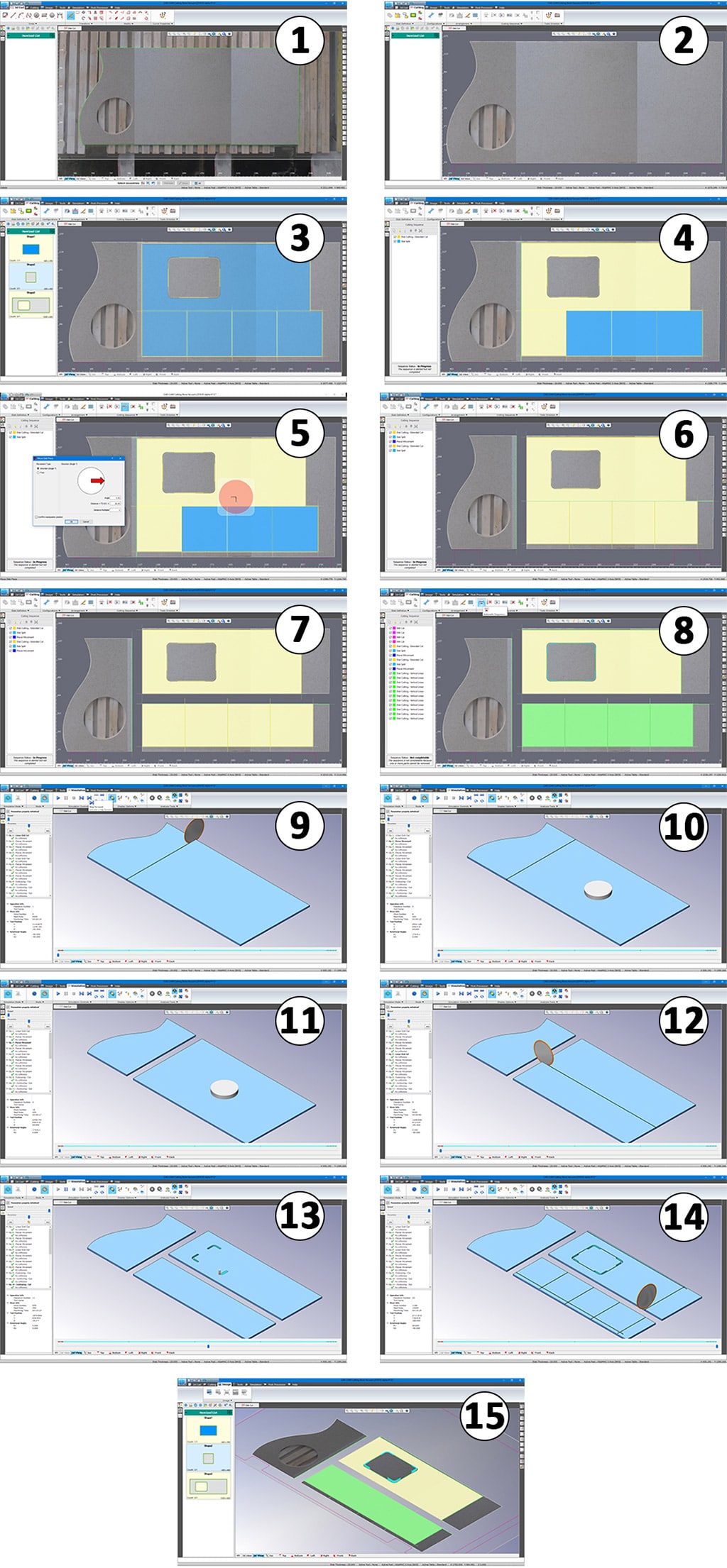

The machine is supplied with a program that allows work in manual.It’s included with the machine a CAD/CAM program (installed on a windows PC made available by the customer), with functions to import slab pictures, automatic cutting process and movement of parts with the vacuum.