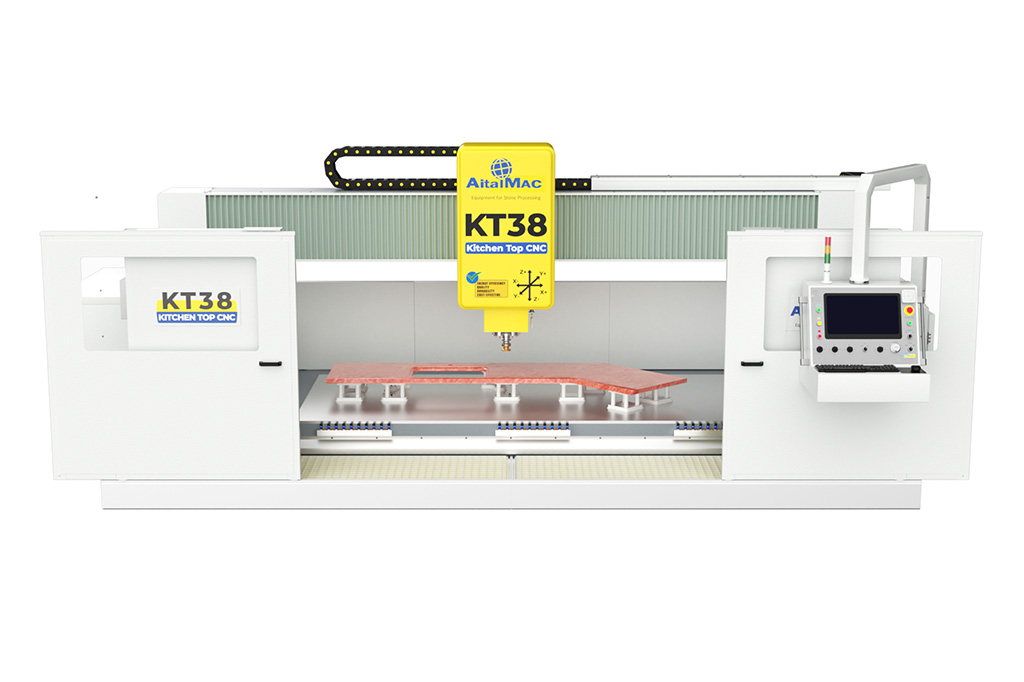

Kitchen Top CNC KT38

The KT38 is a powerful 3 Axis CNC machine, designed to be the ideal stone working center.The included program is realized to facilitate the interaction between operator and machine, especially thought for kitchen sink cutouts, it can import and work with DXF (AutoCAD) files and “G-code” ( RS-274 machine tool programming language) the program among other things shows the operator the right placement of the vacuum pods, and of the parts to work, it allows the machine to work with more tools mounted on the same tool holder, and has automatic and dynamic compensation to account for the wear of tools, so the machine will always achieve a perfect polish.

The absolute precision of the movements is guarantee by a state of art transmission on linear ball guides, moved by brushless motors through zero backlash gearbox and high precision inclined racks.

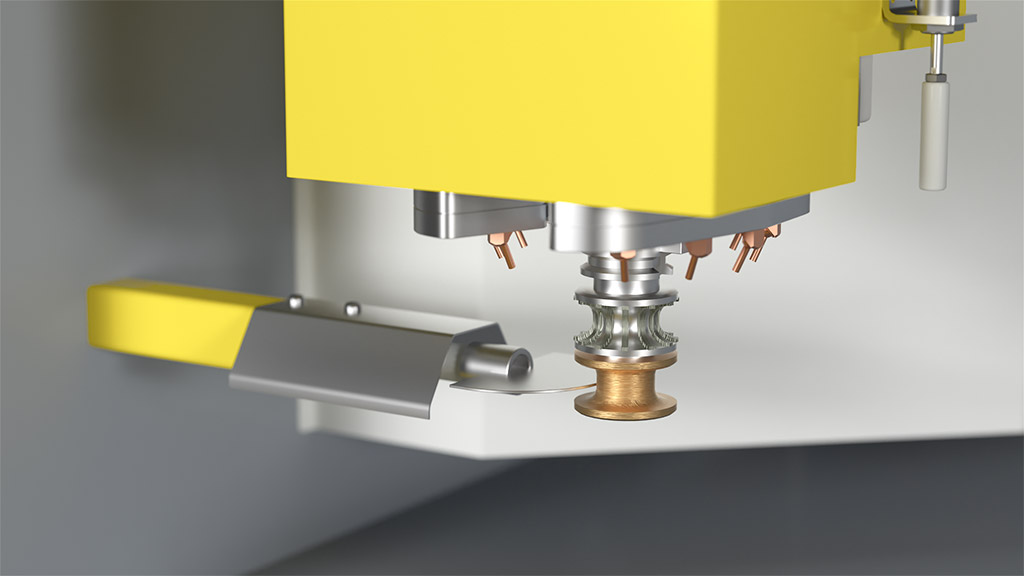

The 13kW electrospindle with automatic tool change has a torque of 72.6Nm in S1 (highest torque of any stone working center) and is controlled in speed from 0 to 9000(14000 RPM, the spindle with high speed ceramic bearings has internal trough spindle and external water cooling for the tools, compatible with standard ISO/BT40 tool holders.

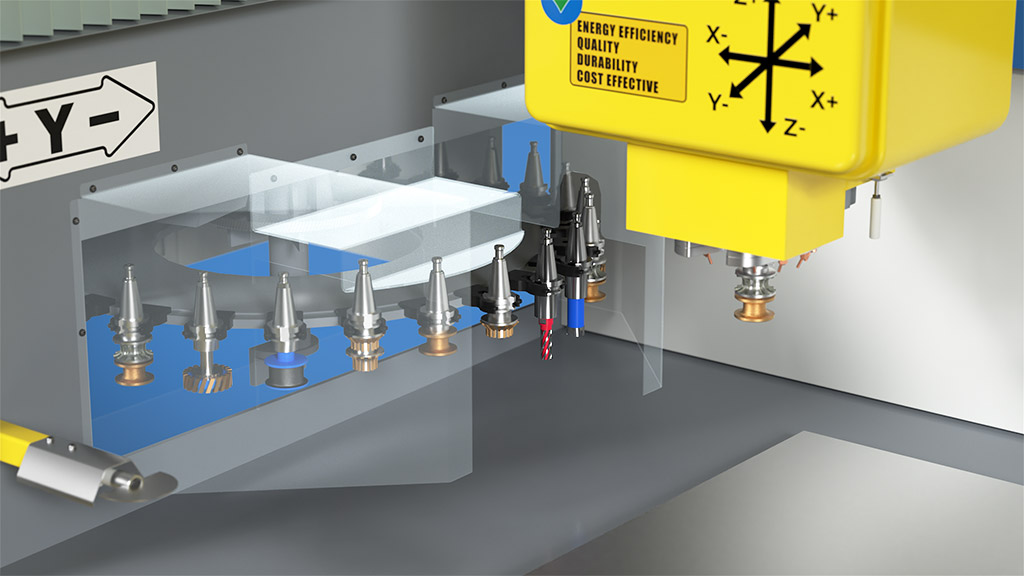

The machine comes standard with 27 automatic tool change stations on a tool carousel optionally extendible to 108.

The machine has 3 interpolated axis X, Y (REAL gantry controlled), Z, controlled by Aitek’s CNC online monitoring system capable of 9 axis interpolation.

The machine comes with a water centrifugal vacuum pump (LRVP) in stainless steel, made for creating vacuum without troubles even if muddy water is introduced in the vacuum system.

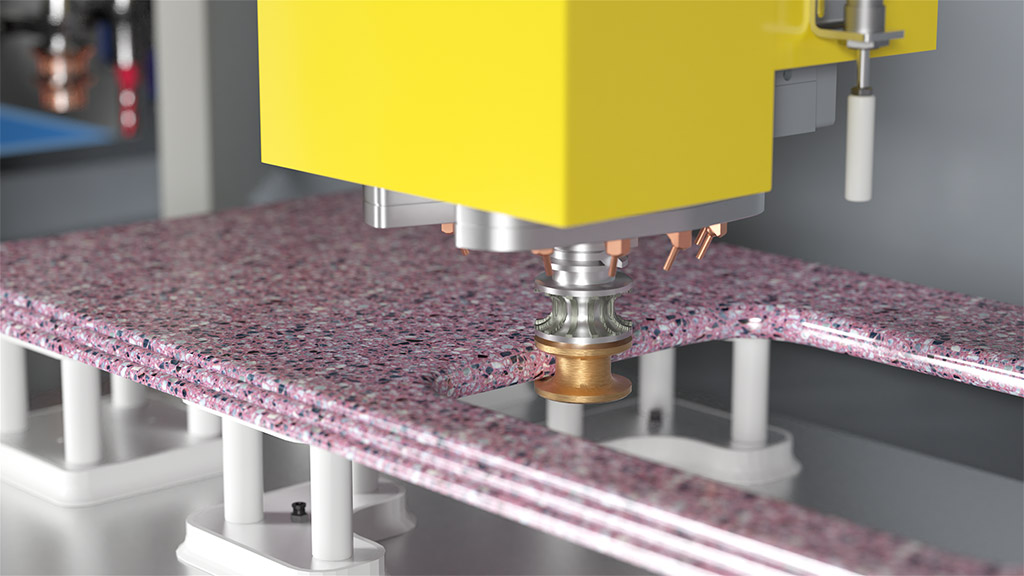

Other options include the left and right spindle group tilt; this option allows the machine to make polished drain boards for kitchen tops.

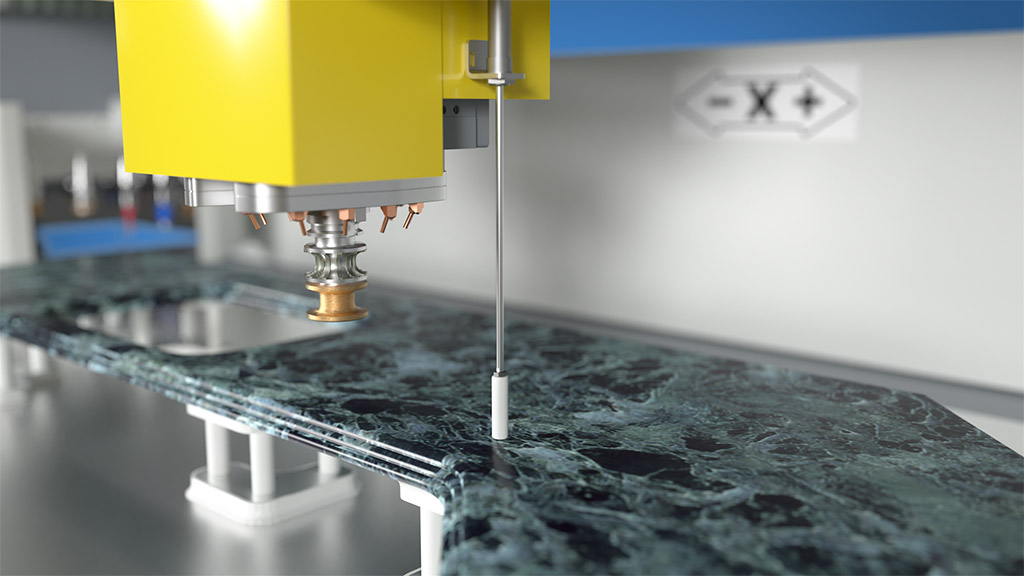

Also optional the surface probe, this option allows the machine to work parts with inconstant thickness with the polished side up.

The machine can also optionally mount a tool diameter probe, to automatic measure tools diameters.

The last option is the saw aggregate, this aggregate requires an added brushless motor for the C axis, the torque of the tool used will be redirected by the aggregate to the electrospindle, the orientation of the aggregate is controlled by the additional C axis, this optional aggregate makes it possible to automatically produce polished sink cut outs with sharp corners, to drill holes on the edge of parts, to cut stone with a small blade and to make and polish draining grooves with shaped blades.

The machine with the optional CAM program is capable of processing complex 3D engraving jobs out of stone blocks like a basin or a bust, the machine can read G-code up to hard drive size with a maximum working speed of 6000mm/min and a precision of 0.01mm.

The machine works with standard 3D G-codes, G-codes can be generated from any commercial CAM, the machine is capable of engrave writing, doing bas-relief and so on. The only limit is the capability and the fantasy of the operator.

Diameter Probe

The machine can optionally mount a tool diameter probing, to automatically measure tool diameters.

Double Tools

The machines with automatic tool change also support more than one contouring tool mounted on the same cone (only with AiTEK CAM).

Auto Table

The Auto Table (optional) Covered with suction cups, that can better for stone processing

Thickness Probe

An optional surface probe allows the machine to work a slab with inconsistent thickness,while leaving the polished side up.

Automatic Tool Change Stations

The machine comes standard with 27 automatic tool change stations on a tool carousel (optionally extendable to a possible 108.)

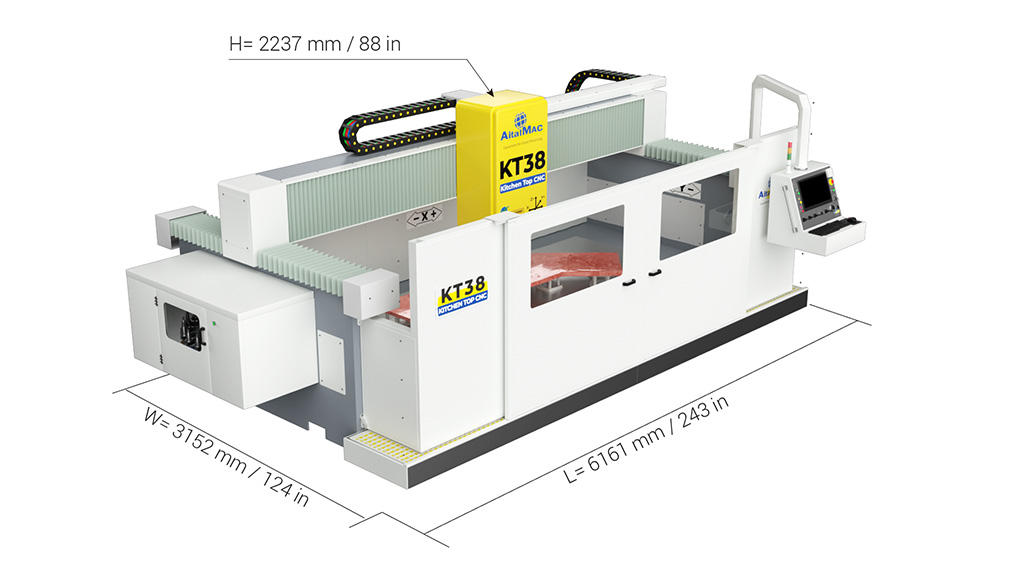

Technical date

| Overall dimensions | 6161×3152×2237 mm/243×124×88 in |

|---|---|

| Total weight | 4200 kg/9260 lbs |

| Max. Install power | 23 kW |

| Linear axis travel (X-Y-Z) | 3720-1775-420 mm/147-70-17 in |

| Max linear speed (X-Y-Z) | 40-40-12 m/min / 131 131-39 ft/min |

| Max. spindle nose to table | 540 mm / 21-1/4 in. |

| Electric spindle power | 15kW(S1) |

| Maximum spindle rotation | 9000 RPM |

| Maximum tool diameter | 120 mm / 4-3/4 in. |

| Tool holder cone | Cone ISO 40 |

| Automatic tool change stations | 27 (54 Optional) |

| Vacuum pump motor power | 1.5 kW |

| Vaccum pump capacity | 0.45 m³/min |

| Air pressure required | 7 bar |

| Water consumption | 20~50 l/min / 5~13 gal/min |