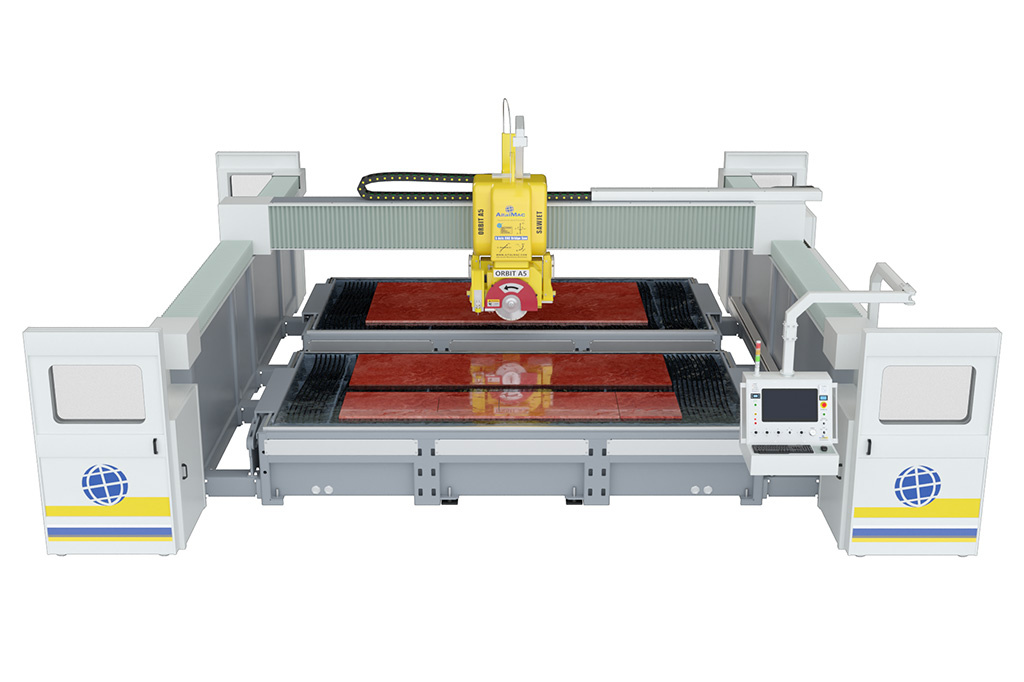

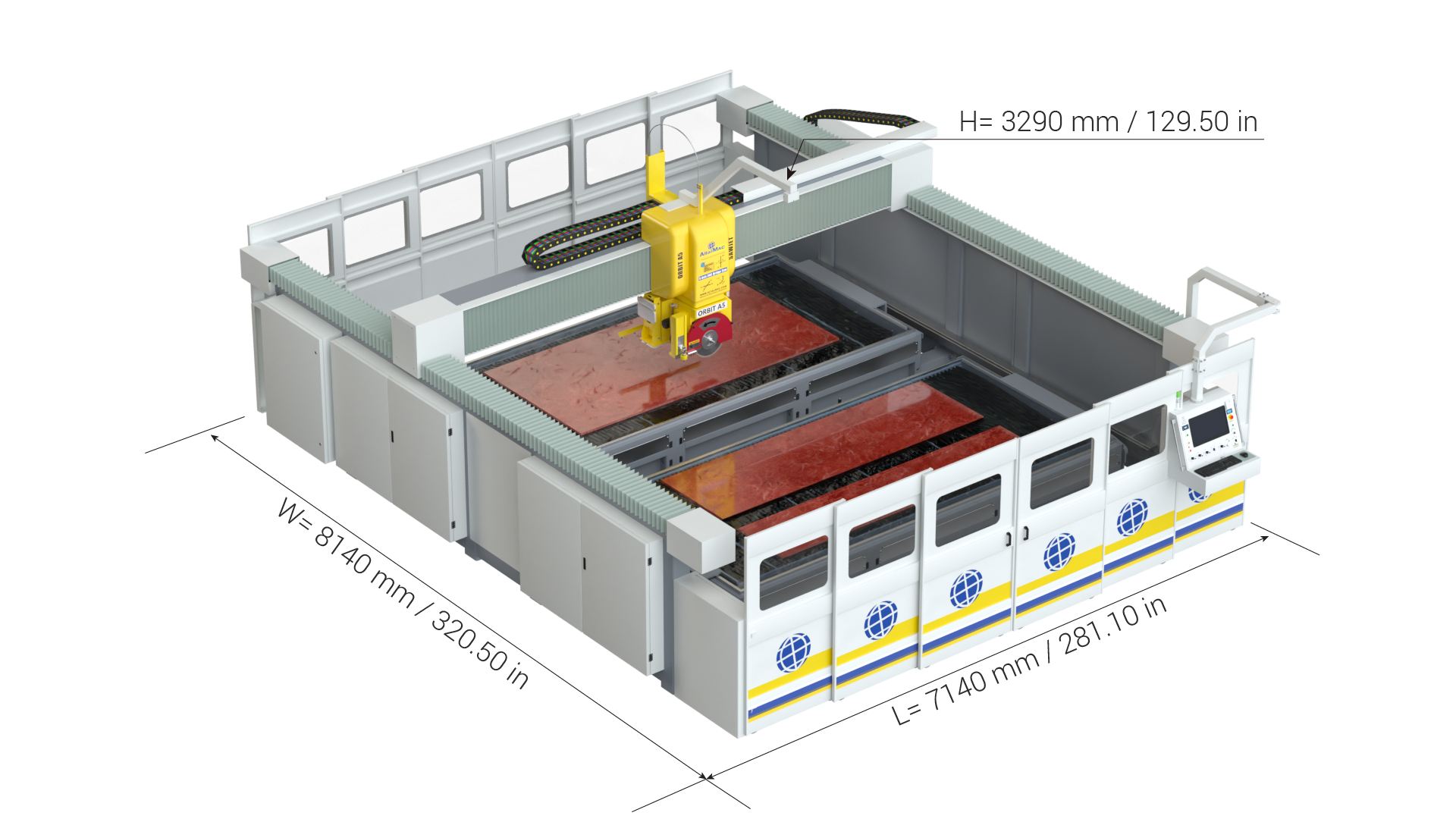

5 axis stone CNC Sawjet Double Table Orbit A5

This stone CNC Sawjet Double Table & bridge saw has everything a technologically advanced bridge saw & waterjet needs to have today: 5 interpolated axis, spindle with half inch fitting with trough-spindle lubrication, tilting table up to 85°(Optional), vacuum manipulator system for parts movement during automatic cut process, on-board camera, blade presetting and stone thickness probe.The machine in details

- Waterjet 5 axis.

- This machine is a fully interpolated 5 axis bridge saw. The Y axis is moved by a gantry system. This guarantees a perfect square of the bridge. Automatic head rotation from 0° to 400° combined with automatic blade tilting from 0° to 90° makes it suitable for large production runs, at the same time containing costs.

- The absolute precision of the movements is guarantee by a state of art transmission on linear ball guide, moved by brushless motors through high precision helical gears and racks.

- CNC Sawjet & bridge saw machine comes with the “absolutely zero” technology, which allow the machine to work without doing the homing process.

- It has an extremely easy to use interface, realized to facilitate the interaction between the operator and the machine.

- CNC Sawjet & bridge saw can quickly do easy cuts in manual, the machine also can import and work with DXF (AutoCAD) files and “G-code” ( RS-274 machine tool programming language).

- The cable-drag chain and the electric cables used on the machine are purposely made for use at high speed (robot materials).

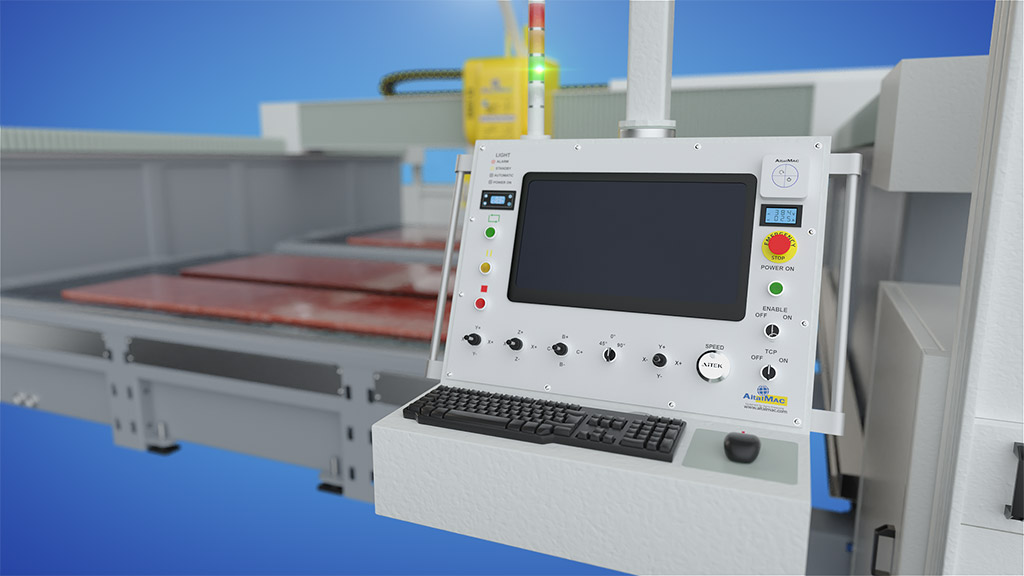

CNC Controller & Software

Easy to use interface. Imports and works with DXF files and G-Code, but can also do simple cuts in manual mode.

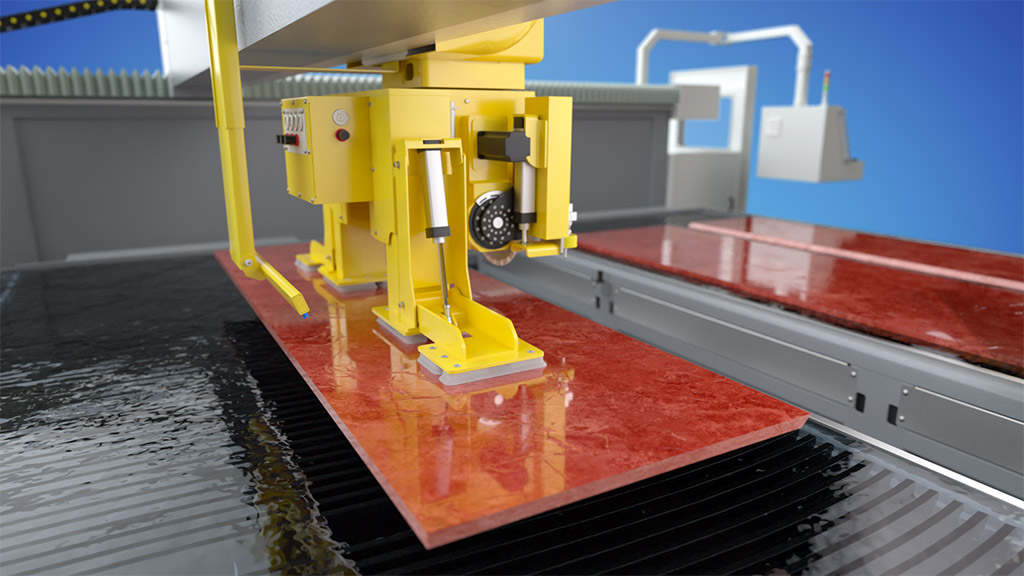

5 axis cutting head and Waterjet

Can miter and interpolate in any direction .

Vacuum manipulator system

The manipulator system has four vacuum cups, enabling a lift capacity of 500kg / 1100lbs.

Washing apparatus

Included in the machine a slab washing apparatus that isusedtowhash the stone before the vacuum manipulations.

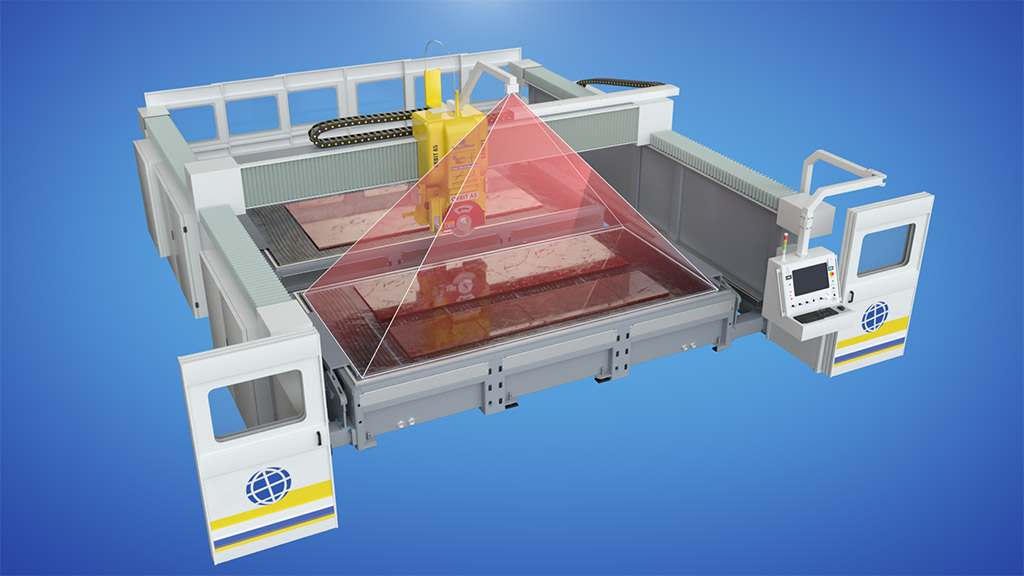

On-board camera

The machine is supplied with an on-board camera with a precision of +/- 5mm. With the camera is possible to snap a picture of the slab, and then import the picture in the program to place your parts avoiding defects.

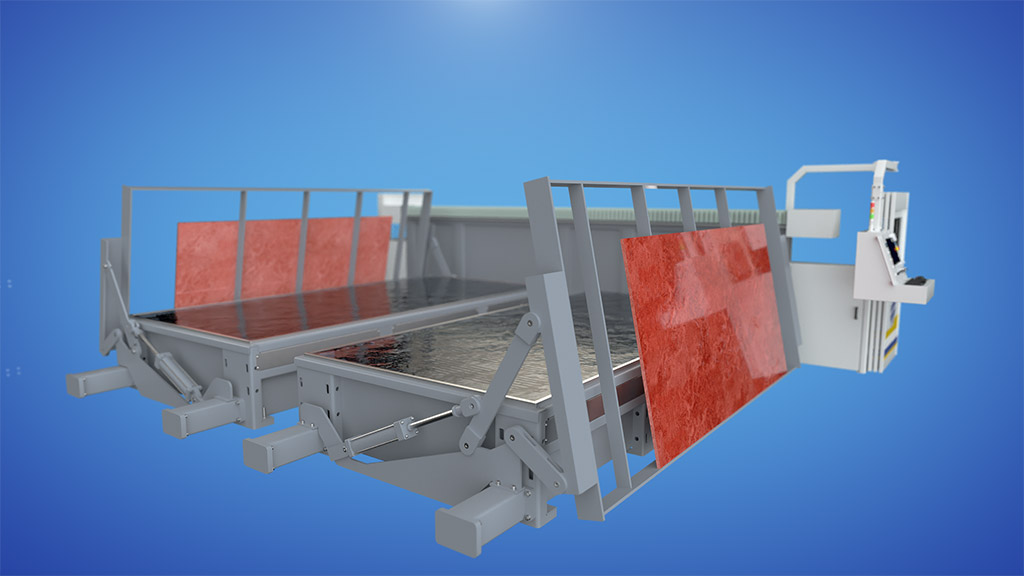

Tilting table

Table tilts up to 85°, enabling the easy loading of your slabs.

| Overall dimensions | 8140×7140×3290 mm/320.5×281.1×129.5 in |

|---|---|

| Total weight | 17000 kg/37479 lbs |

| Max. Install power | 22 kW +18 kW(WJ) |

| Sawjet table size | 4410×2100 mm/174×83 in(A Table size) |

| Linear axis travel (X-Y-Z) | 4420-5900 -380 mm/174 -232 -15 in |

| Rotary axis travel (B-C-V) | 90°-540°-65° |

| Max linear speed (X-Y-Z) | 50-50-8 m/min / 164-164-26 ft/min |

| Max rotation speed (B&C) | 3600°/min |

| blade diameter | 300-500 mm/12-20 in |

| Cutting disc hole diameter | 50 mm/1.96 in |

| Cutting disc flange diameter | 200 mm/7.87 in |

| Max cut thickness vertical | 150 mm/5.9 in |

| Electric spindle power | 15 kW(s1) |

| Maximum spindle rotation | 9000 rpm |

| Maximum pressure of Sawjet | 52000psi |

| Maximum angle of Sawjet | 60° |

| Maximum diameter of CNC tools | 100 mm/3.9 in |

| Vacuum cups | 4 number |

| Vacuum lift capacity | 500 kg/1100 lbs |

| Air pressure required | 7 bar |

| Sawjet water pressure required | 2 bar |

| Water consumption | 20~30 l/min / 5.3~7.9 gal/min |